Equipment name:

(DN1-DN2)*L flue duct, tower winding machine

Note: The range of DN1 (minimum diameter) and DN2 (maximum diameter) should be stated when ordering. The selection range of L: L≤10000mm

Note: The order of D1 (minimum diameter) and D2 (maximum diameter) should be stated when ordering. L can be based on the maximum diameter of the product, L≤10000mm.

The main components of the winding machine are: winding machine rotary head, winding machine moving tail, trolley workbench, winding trolley, resin supply system, roving-drawing system, demoulding system.

Scope of application:

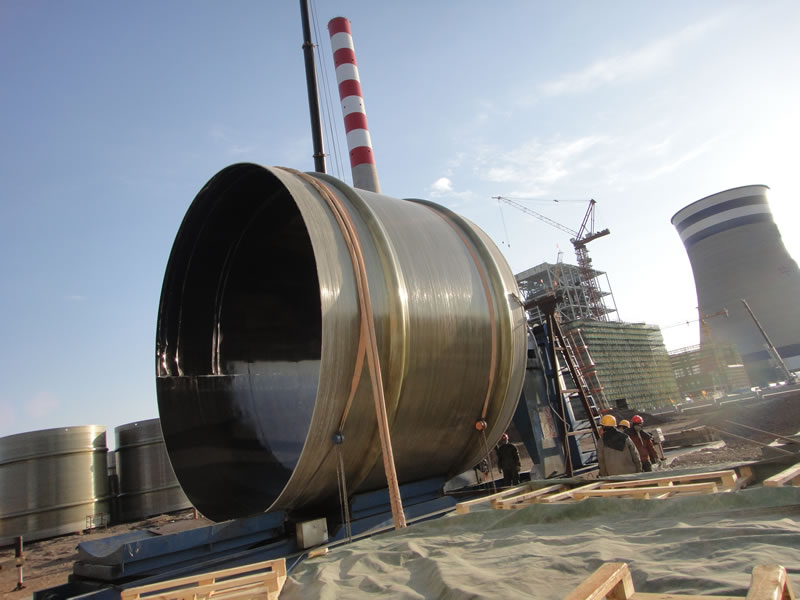

It is suitable for the production of FRP pipes with diameter Ф4000-8500mm and length not longer than 10000mm.

This machine is a special equipment for the production of FRP flue duct and tower on site. It is mainly used for liner making, structural layer production and demoulding. It is an integrated machine for liner making, winding, curing and demoulding.

Main parameters and characteristics:

(1) Winding angle: 60-89°

(2) Width of yarn: 0~300mm

(3) Yarn arranged precision: ±1㎜

(4) Roving-drawing speed: 50~120m/min

(5) Max length of winding: 10000mm

(6) Max winding diameter: 8500mm